D671F Pneumatic Wafer Butterfly Valve Series

manufacturer: Kaiweixi Valve Group Co., Ltd

Eml: Carrie@kaiweixi.com

Tel: +86 (577) 67038872

Mob: +86 189 6779 6392(WeChat Same Account)

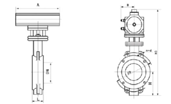

product drawing

D671F Pneumatic Wafer Butterfly Valve Series

Overview

The D671F Pneumatic Wafer Butterfly Valve is an automated valve designed for rapid on/off operation or flow regulation of pipeline media. It utilizes a wafer-type connection and is powered by compressed air to actuate a 90-degree rotation of the disc. The valve operates by converting pneumatic pressure from its actuator into rotary torque, which directly drives the valve stem and disc assembly within the valve body. The sealing surface of the disc is typically lined with high-performance elastomeric materials such as Fluorocarbon Rubber (FKM) or Ethylene Propylene Diene Monomer (EPDM), forming an interference-fit soft seal against the internal valve seat. The wafer design features a compact body that can be directly clamped between two pipeline flanges, ensuring simple and quick installation. Known for its quick response, ease of operation, and compatibility with remote and automated control systems, this pneumatic wafer butterfly valve is widely used in fluid control applications across industries such as food and beverage, pharmaceuticals, water treatment, and chemical processing.

Features

1、Rapid Pneumatic Actuation: Equipped with double-acting or single-acting pneumatic actuators, the valve utilizes compressed air for rapid opening and closing (fastest operation within 0.5-2 seconds), enabling remote automatic control. It is ideal for applications requiring frequent operation.

2、Compact Wafer Design: The wafer-type connection provides a short face-to-face length and lightweight construction, minimizing installation space requirements. The valve is easily clamped between pipeline flanges, making it suitable for confined environments.

3、Soft Seal, Zero Leakage: The disc seal ring is made of high-performance materials such as Fluorocarbon Rubber (FKM) or Ethylene Propylene Diene Monomer (EPDM), offering excellent elasticity and media resistance. It ensures bidirectional sealing, achieving a leakage class up to VI (zero leakage).

4、Low Flow Resistance Design: When fully open, the disc aligns parallel with the media flow direction, resulting in minimal flow resistance. This effectively reduces pressure loss within the pipeline system and conserves energy.

5、Multiple Material Options: The valve body is available in materials including ductile iron, stainless steel, and carbon steel. Internal components and sealing materials can be selected based on media characteristics, ensuring excellent corrosion resistance and adaptability.

6、Easy Maintenance: Its simple design allows for easy disassembly. The seal rings can be replaced without specialized tools, enabling online maintenance and reducing downtime and costs.

7、Compatibility with Smart Control: The valve can be fitted with accessories such as solenoid valves, positioners, and limit switches for seamless integration with automation systems like PLC and DCS, enabling precise on/off control or proportional regulation.

8、Long Service Life: The sealing surfaces employ wear-resistant elastomeric materials, combined with precision-engineered pneumatic actuators, ensuring extended service life even under conditions of frequent cycling.

Dimensions & constructral diagram

D671F Pneumatic Wafer Butterfly Valve Series constructral diagram(pic1)

The main technical parameters

| Name | Materials |

|---|---|

| Pneumatic Actuator | Aluminum Alloy (Cylinder Body) + Carbon Steel (Accessories) |

| Valve Stem | Stainless Steel (Grade 316, Corrosion-Resistant) |

| Disc | Carbon Steel (Base) + Polytetrafluoroethylene (PTFE Lining) |

| Sealing Element | Polytetrafluoroethylene (PTFE) or Fluoroelastomer |

| Valve Seat | Polytetrafluoroethylene (PTFE) |

| Bolt / Nut | Stainless Steel (Grade 316, Corrosion-Resistant) |

| Valve Body | Carbon Steel (Base) + Polytetrafluoroethylene (PTFE Lining) |

Standard

| Item | Specification | Unit |

|---|---|---|

| Nominal Pressure | 1.6 | PN |

| Strength Test Pressure | 2.4 | - |

| Seal Test Pressure | 1.76 | - |

| Suitable Temperature Range | ≤150 | ℃ |

The main external and connection dimensions

| DN | Principal Overall Dimensions | 0.6MPa | 1.0MPa | 1.6MPa | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| L | H | HO | A | B | D0 | n-d | D0 | n-d | D0 | n-d | |

| 50 | 43 | 63 | 315 | 180 | 65 | 110 | 4-14 | 125 | 4-18 | 125 | 4-18 |

| 65 | 46 | 70 | 330 | 180 | 65 | 130 | 4-14 | 145 | 4-18 | 145 | 4-18 |

| 80 | 46 | 83 | 390 | 245 | 72 | 150 | 4-18 | 160 | 8-18 | 160 | 8-18 |

| 100 | 52 | 105 | 431 | 240 | 72 | 170 | 4-18 | 180 | 8-18 | 180 | 8-18 |

| 125 | 56 | 115 | 455 | 240 | 72 | 200 | 8-18 | 210 | 8-18 | 210 | 8-18 |

| 150 | 56 | 137 | 626 | 350 | 93 | 225 | 8-18 | 240 | 8-22 | 240 | 8-22 |

| 200 | 60 | 164 | 720 | 350 | 93 | 280 | 8-18 | 295 | 8-22 | 295 | 12-22 |

| 250 | 68 | 206 | 800 | 500 | 355 | 335 | 12-18 | 350 | 12-22 | 355 | 12-26 |

| DN | Principal Overall Dimensions | 0.6MPa | 1.0MPa | 1.6MPa | |||||||

| L | H | HO | A | B | D0 | n-d | D0 | n-d | D0 | n-d | |

| 300 | 78 | 230 | 860 | 600 | 350 | 395 | 12-22 | 400 | 12-22 | 410 | 12-26 |

| 350 | 78 | 248 | 883 | 600 | 350 | 445 | 12-22 | 460 | 16-22 | 470 | 16-26 |

| 400 | 102 | 289 | 972 | 600 | 350 | 495 | 16-22 | 515 | 16-26 | 525 | 16-30 |

| 450 | 114 | 320 | 1043 | 750 | 380 | 550 | 16-22 | 565 | 20-26 | 585 | 20-30 |

| 500 | 127 | 343 | 1098 | 750 | 380 | 600 | 20-22 | 620 | 20-26 | 650 | 20-33 |

| 600 | 154 | 413 | 1236 | 750 | 380 | 705 | 20-26 | 725 | 20-30 | 770 | 20-36 |

| 700 | 165 | 478 | 1431 | 750 | 380 | 810 | 24-26 | 840 | 24-30 | 840 | 24-36 |

| 800 | 190 | 525 | 1488 | 750 | 380 | 920 | 24-30 | 950 | 24-33 | 950 | 24-39 |

| 900 | 203 | 620 | 1615 | 1250 | 380 | 1020 | 24-30 | 1050 | 28-33 | 1050 | 28-39 |

| 1000 | 216 | 725 | 1765 | 1500 | 580 | 1120 | 28-30 | 1160 | 28-36 | 1170 | 28-42 |

| 1200 | 254 | 780 | 1976 | 1500 | 580 | 1340 | 32-33 | 1380 | 32-39 | 1390 | 32-48 |